Sourcing LCDs from China feels risky. You worry about poor quality, delayed shipments, and communication issues. This can halt your production and damage your reputation. But finding a reliable factory partner is the key.

When sourcing LCDs from China, you must focus on four key areas: supplier verification, clear technical communication, robust quality control procedures, and understanding the logistics and payment terms before you commit to an order.

I remember a client from Italy, Andrea. He came to us after a terrible experience with another supplier. His story showed me just how important it is to have a clear sourcing strategy. It can be the difference between success and failure.

What is the market share of LCD in China?

Many buyers are surprised by the scale of China’s LCD industry. Understanding its size helps you see why sourcing from here makes sense. It shows you are tapping into the global center of display manufacturing.

China completely leads the global LCD panel market. It holds a market share of over 70%. This makes China the world’s largest and most important producer of LCD displays, from the raw panels to the final modules.

This dominance didn’t happen overnight. It is the result of specific strategies and a unique industrial environment.

Why China Dominates the LCD Market

China’s position as the leader is built on a few strong pillars. The government played a huge role. It provided significant support and investment to grow the domestic display industry. This helped companies build advanced production facilities.

Another key reason is the complete supply chain. In China, you can find everything in one place. You have glass manufacturers, polarizer producers, driver IC designers, and assembly factories all close to each other. This ecosystem reduces costs and speeds up production. That is a major advantage for buyers.

Different Tiers of the Market

The market has different types of players. There are giant corporations and more specialized factories like mine.

| Player Type | Description | Best For |

|---|---|---|

| Panel Giants (e.g., BOE, CSOT) | These are massive companies that produce the raw LCD glass panels. They operate on a huge scale. | Buyers needing millions of standard-sized panels for products like TVs and monitors. |

| Module Factories (e.g., Santop) | We take panels from the giants and assemble them with backlights, PCBs, and custom housings. | Buyers who need customized displays for industrial equipment, medical devices, or other specialized products. |

| Trading Companies | These are middlemen. They connect buyers with factories but do not manufacture anything themselves. | Buyers who need a small quantity of a standard product and prefer a simple transaction. |

Understanding this helps you find the right partner. For custom projects, working directly with a module factory like us is almost always the best choice.

What is the raw material for an LCD screen?

To judge the quality of a display, you need to know what it’s made of. The final performance and price of an LCD are directly tied to the raw materials used. A good supplier should be transparent about this.

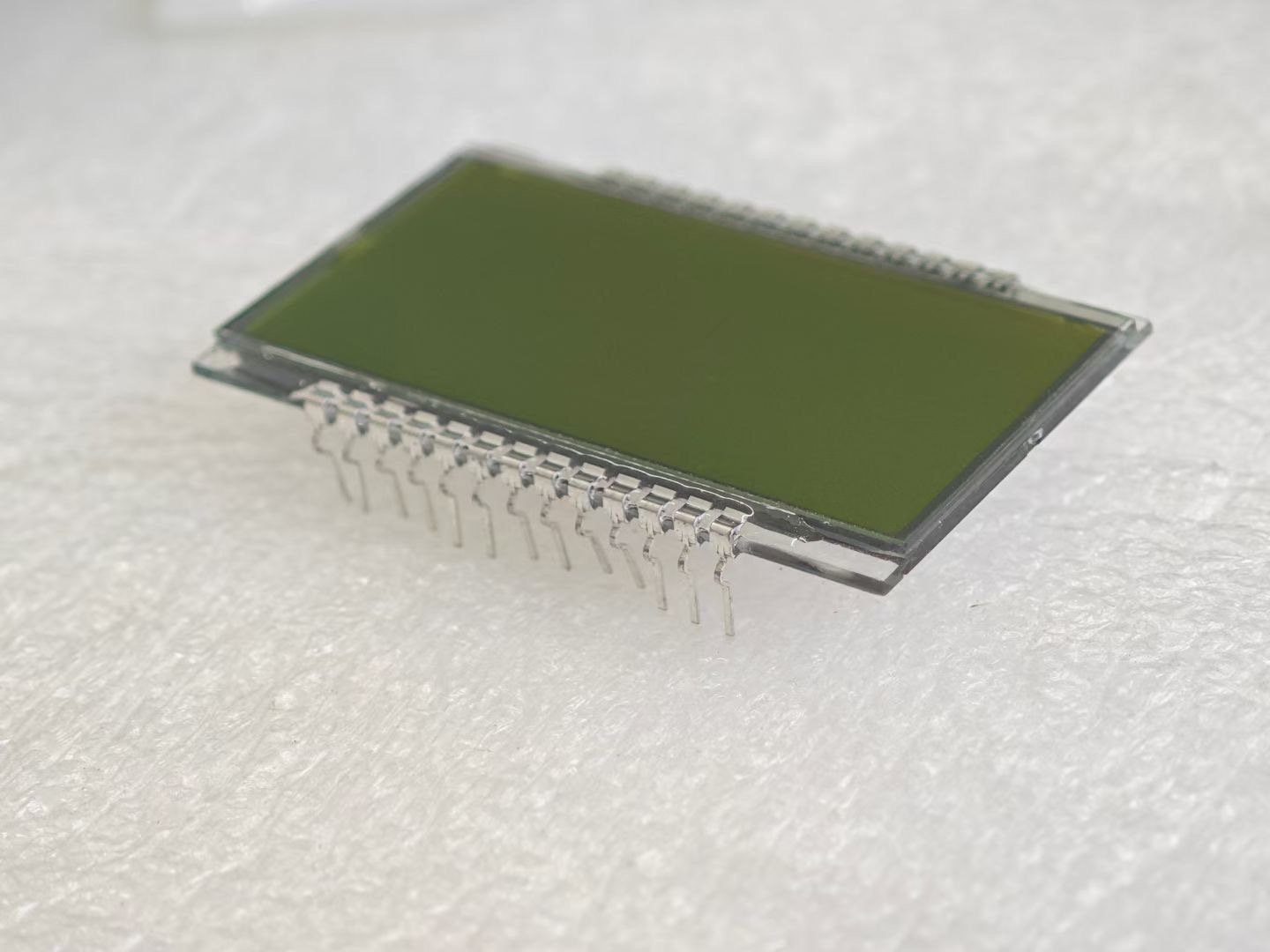

The main raw materials for an LCD screen are liquid crystal, glass substrates, polarizers, color filters, and a backlight unit (BLU). The quality of each component directly impacts the screen’s performance, durability, and cost.

When you receive quotes with different prices, the difference often comes from the quality of these components. Let’s break down what each part does.

Core Components and Their Impact

A lower price might mean the supplier used a lower-grade component. This can lead to problems later. For example, a cheap polarizer can result in a screen with poor contrast and a narrow viewing angle.

Here is a simple table showing the key materials and how they affect quality:

| Component | Main Function | How It Affects Quality |

|---|---|---|

| Liquid Crystal | Controls how much light passes through each pixel. | Determines the screen’s response time and viewing angles. |

| Glass Substrate | Acts as the foundation for all other layers. | Affects the screen’s clarity, thickness, and strength. |

| Polarizers | Two sheets that filter light waves. | Manages contrast and brightness. Low-quality ones can reduce visibility. |

| Backlight Unit (BLU) | Provides the light source for the display. | Impacts brightness, color accuracy, and power consumption. |

| Driver IC | A chip that tells each pixel what to do. | Controls image processing and refresh rate. A good IC prevents flickering. |

| Color Filter | Creates the red, green, and blue subpixels. | Determines the color gamut and accuracy of the screen. |

When I talk with clients like Lorenzo, I always explain these details. It helps them understand why a certain display is priced the way it is. They can then make an informed choice between cost and performance.

How do you inspect an LCD?

You’ve approved the samples and placed your bulk order. The next step is critical: inspection. You cannot assume every unit will be perfect. A proper inspection process protects your investment and your brand.

To inspect an LCD, you must check for visual defects like dead pixels and backlight bleed. You also need to test its electronic performance, including color accuracy and response time. Using a clear checklist is essential for consistency.

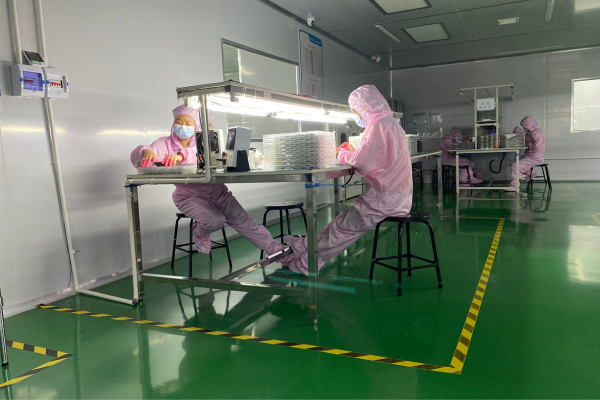

At my factory, we have a multi-stage inspection process. But you should also have your own standards. This ensures that what you receive matches what you ordered.

A Practical Inspection Checklist

Whether you visit the factory yourself or hire a third-party inspector, you need a clear checklist. It removes guesswork and makes the process objective. A good factory should welcome this. They should see it as a way to build trust.

Here is a basic checklist you can adapt for your own needs:

1. Visual Inspection

- Dead or Stuck Pixels: Test this by displaying full screens of black, white, red, green, and blue. Define the acceptable number of pixel defects (e.g., A-grade panels allow 0-5 dead pixels).

- Backlight Uniformity: View a black screen in a dark room. Look for “backlight bleed,” which is light leaking from the edges. Also, check a white screen for dark spots or uneven brightness.

- Physical Defects: Check for scratches on the screen, cracks in the frame, or dust trapped between the layers. Ensure all connectors are secure.

2. Functional Inspection

- Color Accuracy: Display a standard color chart. Check if the colors look natural and match your reference.

- Viewing Angles: Look at the screen from different angles (top, bottom, left, right). The image should not distort or lose color significantly.

- Response Time: Play a fast-moving video. Look for “ghosting” or motion blur, which indicates a slow response time.

- Power Test: Turn the unit on and off several times to ensure it works reliably.

Creating a shared standard with your supplier prevents many problems. It makes everyone accountable.

Who makes LCD screens in China?

Many people who are new to sourcing from China get confused by the different types of suppliers. You might be talking to a giant corporation, a small workshop, or a trading company. It is very important to know who you are dealing with.

In China, LCD screens are made by two main groups: huge panel manufacturers like BOE and TCL-CSOT, and specialized module factories like us, Santop. For custom displays, working directly with a module factory is usually the best option.

Choosing the right type of supplier depends entirely on your business needs.

Panel Manufacturers vs. Module Factories

The giants like BOE produce the raw glass “cells.” They are incredibly efficient at making millions of standard-sized panels. But they have very high minimum order quantities (MOQs). They also offer little to no customization. If you need 100,000 standard 10.1-inch panels, they are a great choice.

But most of my clients need something more specific. They need a custom FPC cable, a special logo printed on the glass, or a unique backlight brightness. This is where module factories like Santop come in.

We are like an LCD supermarket with a custom workshop. We source the glass cells from the giants. Then, in our 30 production lines, we assemble them with custom PCBs, backlights, touch panels, and frames. We create the finished product that our clients can integrate directly into their devices. We offer low MOQs and deep customization.

The Role of Trading Companies

Trading companies are resellers. They don’t own a factory. They find a factory to make your product and add a margin for themselves. This can be easy for simple orders. But for technical products like LCDs, it can cause problems. Communication can be slow, and details can get lost. You also have less control over quality. Andrea’s first bad experience was with a trader who promised things the factory couldn’t deliver.

For serious buyers, I always recommend working directly with a factory. You get better communication, more control, and a better price.

Conclusion

Sourcing LCDs from China is straightforward with the right partner. Focus on supplier verification, clear communication, and a solid quality plan to ensure success.