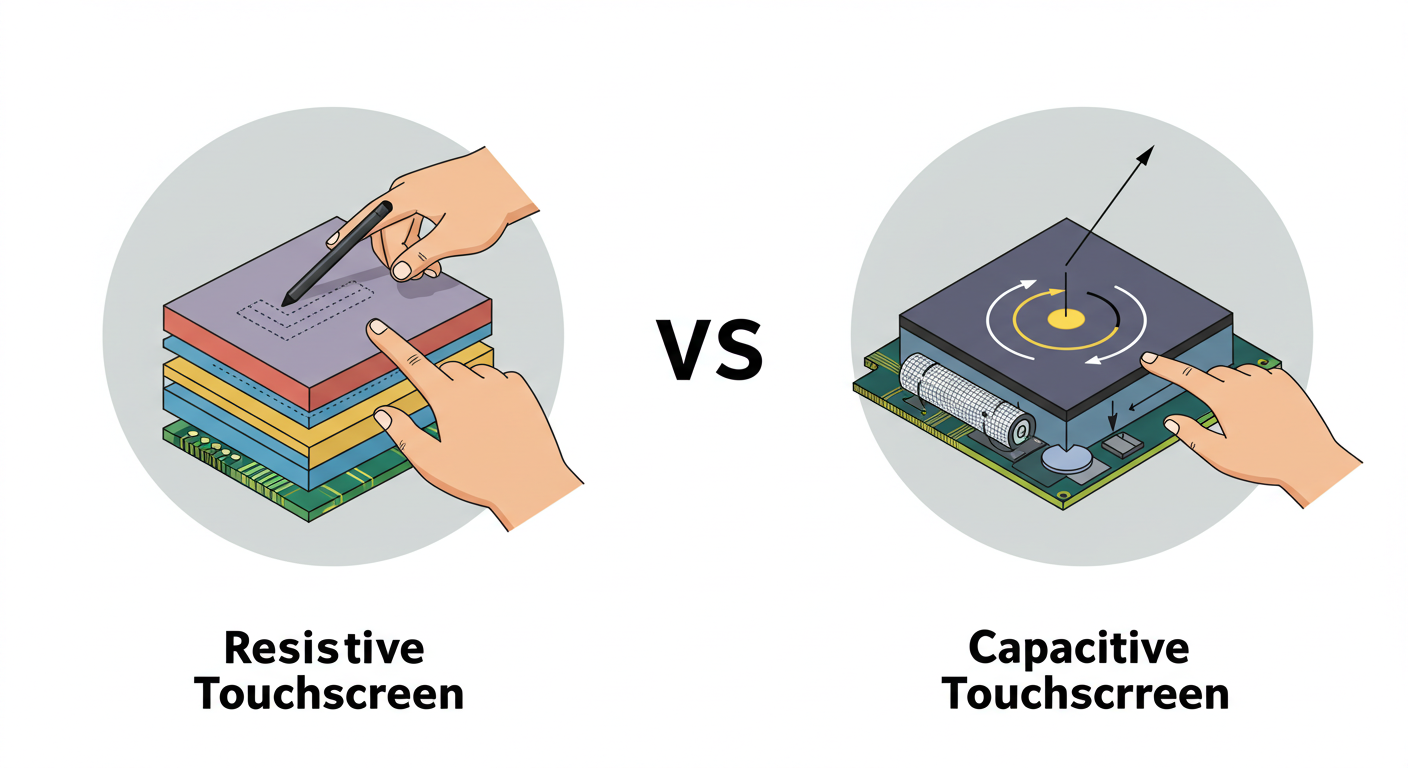

Resistive and capacitive screens feel the same at first, but they work in totally different ways. Understanding the difference helps us make smarter choices.

A resistive screen uses pressure to detect touch, while a capacitive screen senses the electrical charge of your finger.

I used to confuse the two all the time—until I started sourcing LCD modules for my clients. That’s when I realized the wrong choice could delay a whole shipment or affect the user experience.

Which is better capacitive or resistive touch screen?

Most people want to know which is better—but “better” depends on where and how you use the screen.

Capacitive screens are better for modern, multi-touch applications; resistive screens are better for industrial or outdoor use.

How to compare them?

Let’s break it down by features:

| Feature | Capacitive | Resistive |

|---|---|---|

| Touch method | Finger only (or capacitive stylus) | Any object (stylus, glove, etc.) |

| Multi-touch support | Yes | No |

| Durability | Moderate | High (less fragile surface) |

| Clarity and brightness | Higher | Lower |

| Cost | Higher | Lower |

| Water and dust resistance | Lower (sensitive to liquids) | Higher |

| Ideal use cases | Smartphones, tablets | Industrial panels, POS terminals |

From my experience exporting to Italy and Brazil, many industrial clients still prefer resistive screens for rugged settings, especially in factories or outdoor kiosks. But mobile device manufacturers almost always go for capacitive for better gesture control and image clarity.

How do I know if my touch screen is capacitive or resistive?

It’s not always obvious at first glance. But there are simple ways to test it.

Try touching it with a gloved finger or stylus—if it works, it’s probably resistive. If it doesn’t, it’s likely capacitive.

Other detection methods

1. Check the user manual or part number

If you’re buying modules like I do, the fastest way is to check the product datasheet. Manufacturers (like us) clearly indicate the touch technology.

2. Observe the touch sensitivity

Capacitive screens feel smoother and react instantly, even to light finger touches. Resistive ones need more pressure—you might feel a slight “give” when pressing.

3. Use a conductivity test

Only capacitive screens respond to electrical charge. You can try using a plastic pen. If the screen doesn’t react, it’s likely capacitive.

When I started working with clients from Italy, I often asked them to send a short video of their touch test. This avoided long email threads and miscommunication.

What are the disadvantages of a resistive touch screen?

While resistive screens have their place, they aren’t perfect.

Resistive screens are less responsive, have lower image quality, and don’t support multi-touch.

Where do resistive screens fall short?

Lower responsiveness

They require pressure, so they don’t feel as smooth. Quick taps might not register.

No multi-touch gestures

Forget pinch-to-zoom or swiping with two fingers. This makes them less ideal for modern UIs.

Less light transmission

There are multiple layers in a resistive screen, which reduces clarity and brightness. This is a big issue in devices used under direct sunlight.

Aging issues

The top layer can wear down or get scratched, especially in heavy-use environments.

However, in outdoor terminals or industrial machines, these drawbacks are often acceptable. I had a Russian client who used resistive touch screens in agricultural machinery—gloves, dust, and water were all part of daily operations.

What is the best type of touch screen?

Everyone wants to buy the “best,” but the best choice depends on your real-world application.

Capacitive is best for clarity and user experience; resistive is best for rugged environments or stylus-based input.

Think beyond “best”

I always tell my B2B customers: “Don’t just buy what’s trendy—buy what fits.”

Choose capacitive if:

- You’re designing smartphones, tablets, or car displays.

- You want sleek, modern touch gestures.

- You don’t expect the screen to get wet, dirty, or scratched.

- You’re focused on aesthetics and responsiveness.

Choose resistive if:

- Your users wear gloves or use pens/styluses.

- The environment is dusty, wet, or exposed to harsh conditions.

- You need a lower-cost solution with fewer fragile parts.

- Your UI is simple and doesn’t require gestures.

Hybrid Options

Some suppliers now offer hybrid designs that combine the durability of resistive with the gesture support of capacitive. These are rare and expensive but can be the best of both worlds.

Here’s how I help buyers decide:

- I ask about final application: medical device, POS system, or mobile?

- Then I check usage environment: indoors, outdoors, hot, cold?

- Finally, we discuss budget and target market.

This method reduces mistakes and ensures long-term satisfaction. It also builds trust, which is crucial in B2B deals.

Conclusion

Capacitive is modern and smooth; resistive is tough and versatile.

Need help choosing the best display for your project?

The Santop Display team is here to help and can assist you in finding the best display for your project. Please contact our friendly sales and support team — ready to answer any questions that you may have about these touch display modules or any the displays in the Santop Display catalog.