Are you confused by all the technical terms for touchscreens? Choosing the wrong display can lead to laggy products and unhappy customers. Let’s break down what a capacitive touchscreen is.

A Projected Capacitive (PCAP) touchscreen is a display that detects touch using the electrical properties of the human body. It is known for its high accuracy, responsiveness, and multi-touch capabilities.

I remember meeting a client, Marcos from Brazil. He was looking for displays for his new line of home automation products. He was used to older technologies and was skeptical about the cost of PCAP. This article breaks down everything I explained to him.

What is a PCAP touch screen?

So, let’s start with the basics. Understanding the technology is the first step before you decide to source it for your products. It’s a key decision for any buyer.

A PCAP, or Projected Capacitive, touchscreen has a grid of electrodes. This grid creates an electric field. When your finger gets close, it disrupts this field, and the screen registers a touch.

The Core Components of a PCAP Screen

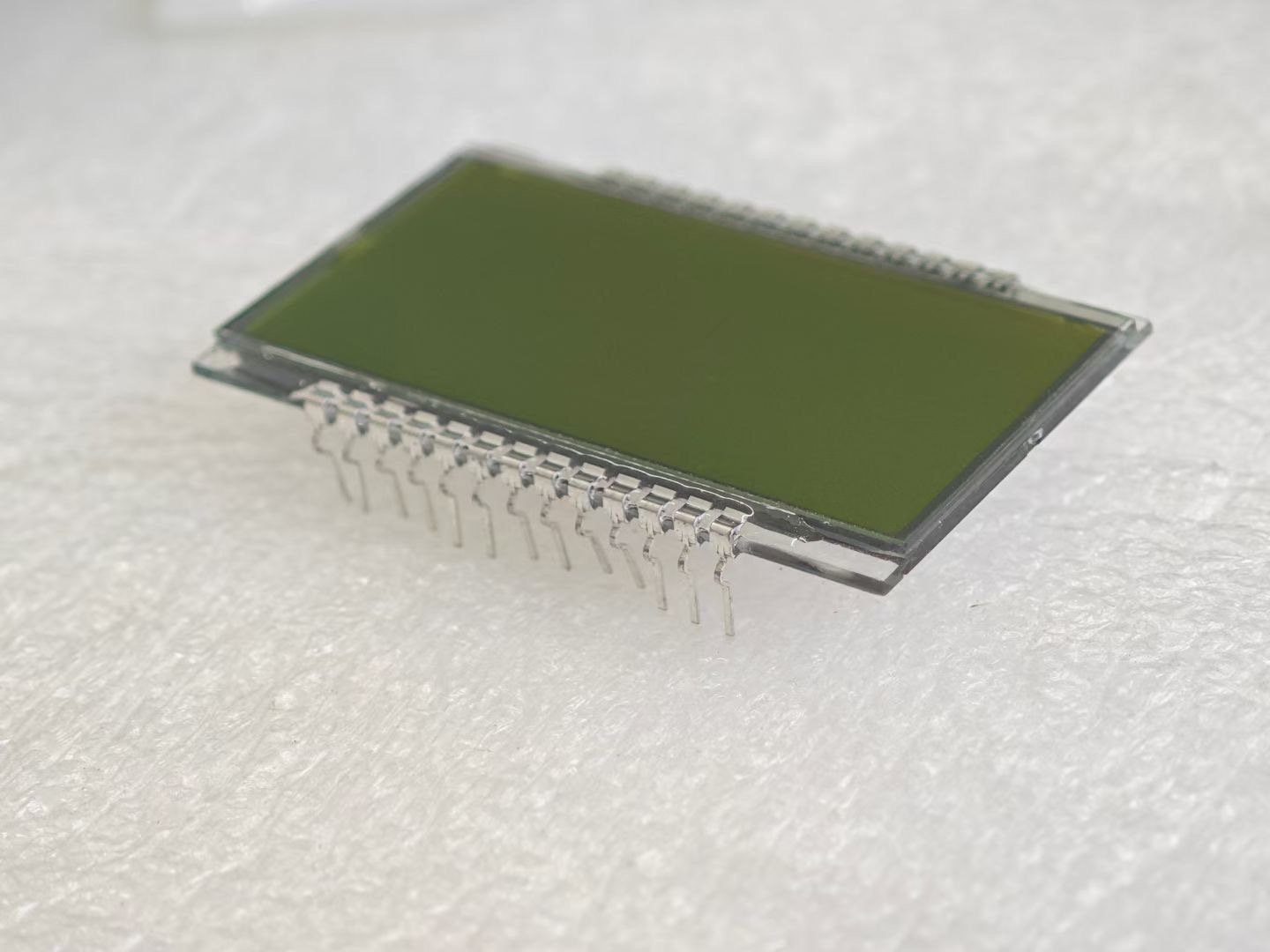

A PCAP screen isn’t just one single layer. It’s a sandwich of different materials working together. Here’s a simple breakdown of its structure:

- Cover Glass: This is the top layer you touch. It’s usually made of durable, scratch-resistant glass. At our factory, we can customize its thickness and even add your brand’s logo.

- Transparent Conductive Layers: Beneath the glass, there are two layers of transparent conductive material, usually Indium Tin Oxide (ITO). These layers are etched to form a grid of X and Y electrodes. This grid is the heart of the sensor.

- Controller Chip: This is the brain. It’s a small integrated circuit (IC) that constantly monitors the electric field of the electrode grid. It processes any changes and sends the touch coordinates to the main system.

- LCD/OLED Panel: This is the display itself, which sits behind the touch panel. It shows the images, and the PCAP panel sits on top to handle the touch interaction.

Surface vs. Projected Capacitive: A Quick Look

You might also hear about “surface capacitive” screens. They are an older, simpler form of capacitive technology. They only have sensors on the corners and can only detect a single touch.

Projected Capacitive (PCAP) is the more advanced version. It uses a dense grid of sensors, which is why it can detect multiple touch points very accurately. Nearly all modern devices, from your phone to an industrial terminal, use PCAP technology.

How does a capacitive touch sensor work?

The way these screens work seems like magic. But it’s just simple physics. Understanding this process helps you appreciate why it’s so reliable for industrial and commercial products.

A capacitive sensor works by detecting a change in capacitance. Your body is a natural electrical conductor. When your finger touches the screen, it changes the electrical charge at that specific point.

The controller chip instantly recognizes this change. It then calculates the exact location of your touch on the screen. This process happens in milliseconds.

The Role of the Controller

The controller is the unsung hero of the touchscreen. Its job is to do two things constantly:

- Scan: It sends a small voltage to the electrode grid, creating a stable electrostatic field across the screen’s surface.

- Detect: It continuously measures the capacitance at every intersection point of the X-Y grid. When your finger approaches, it “steals” a little bit of charge, causing a drop in capacitance at that specific point.

The controller identifies the coordinates of this drop and reports it as a touch event. Because it can monitor the entire grid at once, it can detect and track multiple fingers simultaneously. This is what we call “multi-touch.”

What are Key features and advantages for capacitive touch screen?

So, why do so many buyers like Marcos end up choosing PCAP? It’s because the advantages directly impact the final product’s quality and the end-user’s experience.

PCAP screens offer fantastic image clarity, are very durable, and feel incredibly responsive. They also support multi-touch gestures like pinching to zoom, which modern users expect from their devices.

I always explain to my clients that choosing PCAP is an investment in quality. Here are the specific benefits we see in our products at Santop.

Key Advantages of PCAP Technology

| Feature | Advantage | Why it Matters for Your Product |

|---|---|---|

| Superior Image Quality | The top layer is glass, which has high transparency. | Images from the LCD underneath look brighter and sharper. This is vital for medical devices or high-end consumer products. |

| High Durability | The glass surface is resistant to scratches, water, and dust. | Your product will last longer, even in tough environments like a factory floor or a public kiosk. It reduces returns and repairs. |

| Multi-Touch Support | Can detect and track 10 or more touch points at once. | Users can perform complex gestures like zoom, rotate, and swipe. This makes the interface intuitive and modern. |

| Excellent Sensitivity | Requires only a light touch from a bare finger to work. | The user experience is smooth and effortless. No need to press hard, which makes interaction faster and more pleasant. |

| Easy to Clean | The seamless glass surface has no crevices for dirt to get trapped. | This is crucial for medical and food service applications where hygiene is a top priority. A simple wipe-down is enough. |

What are Applications for capacitive touch screen?

Now that we know how it works and why it’s good, let’s talk about where you can use it. You’ll find PCAP technology in almost every industry today.

Capacitive touchscreens are used everywhere. You can find them in smartphones, car navigation systems, industrial control panels, medical monitors, and retail payment terminals.

At our factory, we produce custom LCDs for a wide range of clients. From a buyer in Brazil needing screens for agricultural equipment to a distributor in Russia for POS systems, the applications are endless.

Common Industries for PCAP Screens

- Consumer Electronics: This is the most famous application. Smartphones, tablets, laptops, and smartwatches all rely on PCAP for their smooth user interface.

- Industrial Automation: In smart factories, PCAP screens are used as Human-Machine Interfaces (HMIs) to control machinery. Their durability against dust and moisture is a huge asset here.

- Medical Devices: Precision and hygiene are key. You’ll see PCAP screens on patient monitoring systems, ultrasound machines, and lab equipment because they are accurate and easy to sanitize.

- Automotive: Modern cars are filled with them. In-dash infotainment systems, navigation, and climate control all use PCAP screens. They need to be reliable and withstand vibrations and temperature changes.

- Retail & Hospitality: Self-service kiosks, Point-of-Sale (POS) systems, and digital ordering menus in restaurants use PCAP for its durability in public settings and ease of use.

What is the difference between PCAP and resistive touch screen?

This is the most common question I get from procurement officers. Marcos asked this too. He wanted to understand why he should pay more for PCAP when resistive screens were cheaper.

The biggest difference is how they register a touch. PCAP uses the electrical charge from your finger. A resistive screen uses physical pressure to connect two conductive layers.

This fundamental difference leads to a completely different user experience and set of features.

PCAP vs. Resistive: A Direct Comparison

I made this table for Marcos to help him decide. It clearly shows the trade-offs.

| Feature | Capacitive (PCAP) | Resistive |

|---|---|---|

| Activation Method | Light touch from a bare finger or conductive stylus. | Firm pressure from any object (finger, glove, stylus). |

| Image Clarity | Excellent. The glass top layer is over 90% transparent. | Fair. The flexible top plastic layer can diffuse light, making images look hazy. |

| Durability | High. The glass surface is strong and scratch-resistant. | Lower. The plastic top layer can be punctured or scratched easily. |

| Multi-Touch | Yes. Standard feature, supports gestures. | No. Can only register a single point of pressure at a time. |

| Sensitivity | Very high and responsive. | Lower. Requires deliberate pressure to activate. |

| Cost | Higher. | Lower. It’s an older, simpler technology. |

I explained to him that while resistive screens can be operated with gloves, the downsides in clarity and durability were significant for his premium product. We even offer custom PCAP solutions at Santop that can work with some gloves, providing the best of both worlds.

Conclusion

Choosing the right touchscreen is a critical decision. Capacitive technology offers a durable, clear, and highly responsive solution ideal for most modern products and demanding industrial applications.