Are you confused by the different LCD connection types? Choosing the wrong one can lead to failures and increase your costs. I will help you understand the key differences.

The main difference is in flexibility, durability, and cost. FPCs are flexible and thin, Metal Pins are robust and reliable for soldering, and Zebra Stripes are solderless, pressure-based connectors for simple displays.

I remember a client from India who was new to sourcing LCD modules. He chose a connector based only on price. This decision ended up costing him more in assembly and repairs. Let’s make sure that doesn’t happen to you.

What is an LCD Connector?

An LCD connector is the essential link between your display and the main circuit board (PCB). It’s more than just a part; it’s the lifeline for your product’s visual interface.

An LCD connector is a component that electrically connects the Liquid Crystal Display (LCD) glass or module to a printed circuit board (PCB). This connection transmits power and data signals to the display.

Think of it like a bridge. On one side, you have the brain of your device, the PCB. On the other side, you have the face, the LCD. The connector is the bridge that allows them to communicate. Without a solid, reliable bridge, the screen stays blank. The type of bridge you choose—be it FPC, Metal Pin, or Zebra Strip—depends on the road (your product design) and the traffic (your application’s demands). Choosing the correct one is the first step to a successful product design.

What is a FPC? What are its Advantages, Disadvantages, and Applications?

Have you seen those thin, flexible, amber-colored “cables” in modern electronics? That is likely a Flexible Printed Circuit, or FPC. It is a very common choice for modern devices.

FPC (Flexible Printed Circuit) is a thin, bendable circuit made of a flexible polymer base. It is ideal for compact and complex devices where space is limited and a flexible connection is necessary.

What is FPC in Detail?

An FPC is essentially a printed circuit board built on a flexible material like polyimide. Instead of rigid fiberglass, it uses a pliable base. This allows it to be bent, twisted, and folded to fit into tight spaces. This makes it a favorite for products like smartphones, cameras, and portable medical devices. The connection is usually made by inserting the FPC tail into a ZIF (Zero Insertion Force) connector on the PCB.

Advantages and Disadvantages of FPC

| Advantages | Disadvantages |

|---|---|

| Space Saving: Very thin and flexible, fits in tight designs. | Higher Cost: More expensive than Metal Pins or Zebra Stripes. |

| Lightweight: Adds almost no weight to the product. | Less Durable: Can be damaged by repeated bending or improper handling. |

| High-Density Connections: Can support many connections in a small space. | Requires a Connector: Needs a mating connector (like ZIF) on the PCB. |

| Good for Vibration: Its flexibility can absorb vibrations well. | Complex Repair: Repairing a damaged FPC or its connector can be difficult. |

Common Applications for FPC

- Smartphones and Tablets: Connecting displays, cameras, and other components.

- Laptops: Used for keyboard, trackpad, and screen connections.

- Medical Devices: In portable monitors and diagnostic tools where space and weight are critical.

- Automotive Displays: For dashboard instruments and infotainment systems.

What is a Metal Pin? What are its Advantages, Disadvantages, and Applications?

When you need a strong, permanent connection, Metal Pins are a classic choice. They are the workhorses of the LCD connection world, known for their reliability and straightforward design.

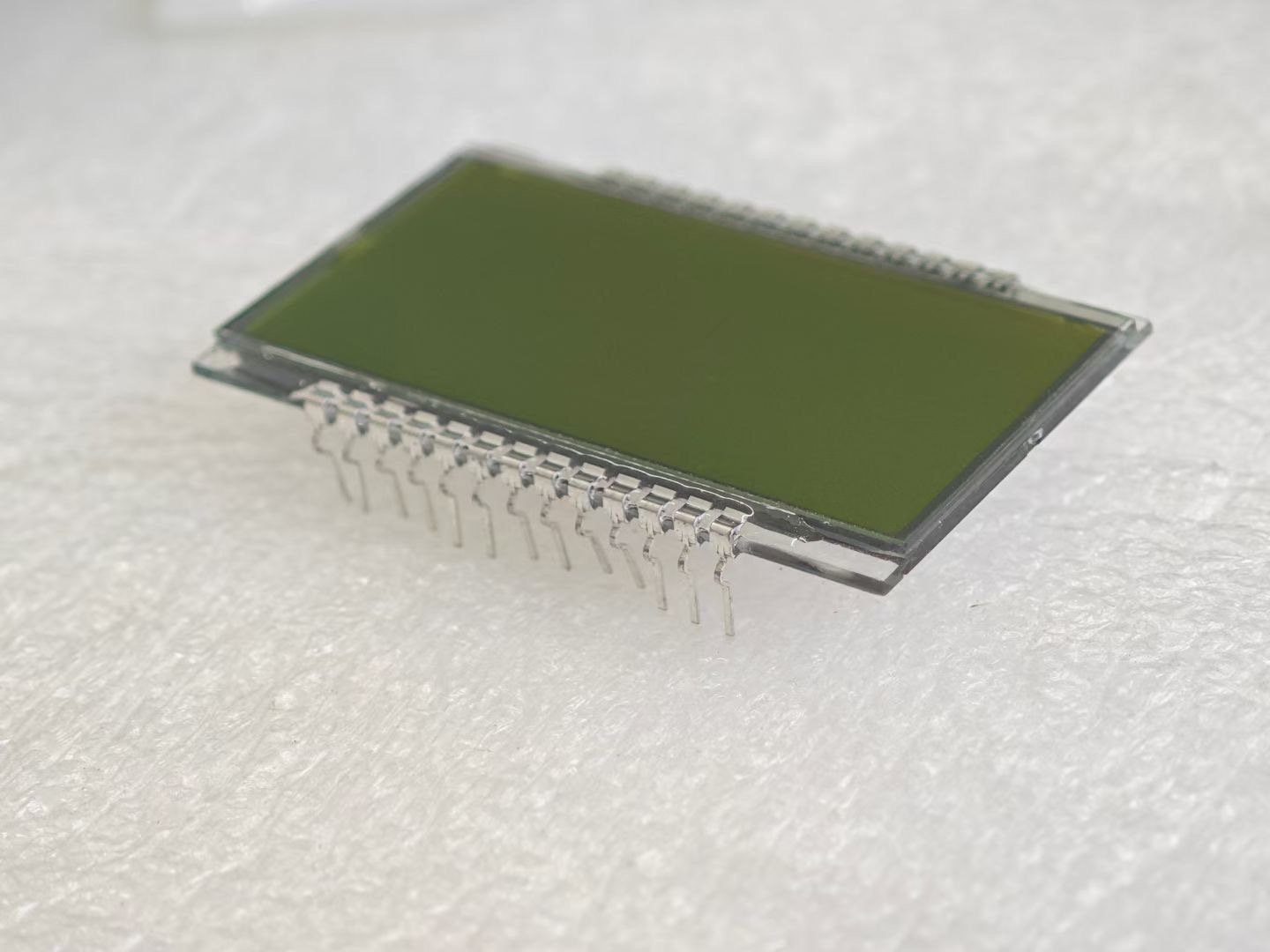

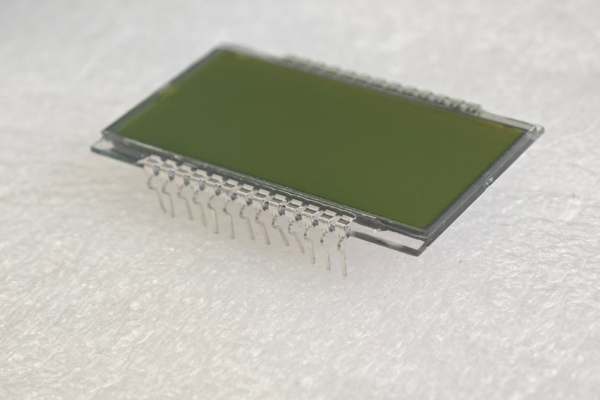

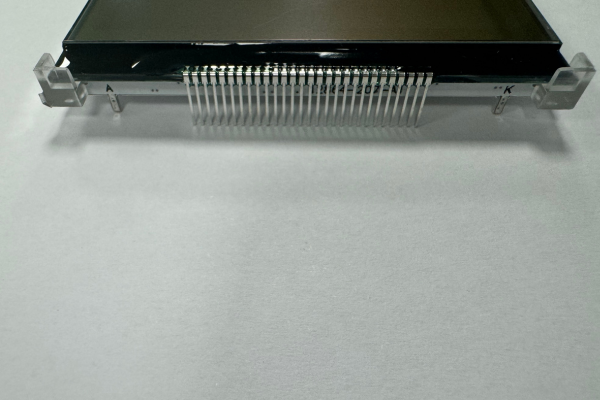

Metal Pins are rigid leads extending from the LCD module. They are designed to be soldered directly onto a PCB or plugged into a socket, creating a very strong and stable electrical connection.

What is a Metal Pin in Detail?

These are simply stiff metal legs, usually arranged in a single or dual row along the edge of the LCD’s own circuit board. They provide a direct, robust connection method. The most common way to use them is through-hole soldering, where the pins go through holes in the main PCB and are soldered on the other side. This creates an extremely secure mechanical and electrical bond. It’s a method I have seen used for years in industrial equipment where durability is key.

Advantages and Disadvantages of Metal Pin

| Advantages | Disadvantages |

|---|---|

| Very Durable: Strong mechanical connection resists shock and vibration. | Bulky: Takes up more vertical space than FPC or Zebra Stripes. |

| Reliable Connection: Soldering provides a permanent, stable electrical link. | Inflexible: The connection is rigid and cannot be bent. |

| Low Cost: The pins themselves are inexpensive. | Assembly Time: Soldering each pin can be time-consuming. |

| Easy to Inspect: Solder joints are easy to visually inspect for quality. | Difficult to Rework: Desoldering can be challenging and may damage the PCB. |

Common Applications for Metal Pin

- Industrial Control Panels: Where devices must withstand harsh environments.

- Medical Equipment: For stationary devices like infusion pumps and patient monitors.

- Home Appliances: In devices like microwaves, washing machines, and thermostats.

- Test and Measurement Instruments: Multimeters and oscilloscopes often use pin-connected displays for their ruggedness.

What is a Zebra Strip? What are its Advantages, Disadvantages, and Applications?

Imagine needing to connect an LCD glass directly to a PCB without any soldering. This is where the Zebra Strip comes in. It’s a clever and cost-effective solution for simpler displays.

A Zebra Strip, or elastomeric connector, is a small strip of rubber with alternating conductive and non-conductive layers. It creates a connection when compressed between the LCD and the PCB.

What is a Zebra Strip in Detail?

The name “Zebra” comes from its striped appearance. It’s made of silicone rubber, with very thin layers of conductive carbon-filled rubber alternating with non-conductive silicone layers. When you place it between the contact pads on the LCD glass and the pads on the PCB, and apply pressure with a bezel or frame, the conductive layers form tiny bridges for the electrical signals. The non-conductive layers prevent short circuits between adjacent pads. It’s a simple, solderless, and easily replaceable connection method.

Advantages and Disadvantages of Zebra Strip

| Advantages | Disadvantages |

|---|---|

| Solderless: Easy and quick assembly, no heat required. | Requires Pressure: Needs a bezel or frame to maintain constant pressure. |

| Low Cost: One of the cheapest connection methods available. | Sensitive to Misalignment: Must be perfectly aligned for all connections to work. |

| Easy to Replace: If there’s a problem, you can just swap the strip. | Not for High-Density: Best for displays with lower pin counts. |

| Shock Absorption: The rubber material helps absorb minor shocks. | Environmental Sensitivity: Can be affected by extreme temperatures or humidity over time. |

Common Applications for Zebra Strip

- Digital Watches and Clocks: A classic use for simple segment displays.

- Calculators: Connecting the simple numeric LCD to the main board.

- Gasoline Pumps: For the digital price and volume displays.

- Basic Digital Meters: In simple devices that show numeric readings.

How to Clean an LCD Connector?

A dirty connector can cause flickering, missing lines, or a completely blank screen. Proper cleaning is a simple step that can solve many common display problems and save you money.

To clean an LCD connector, gently wipe the contact points with a lint-free swab lightly dampened with Isopropyl Alcohol (IPA). Ensure the power is off and the parts are completely dry before reconnecting.

Tools You’ll Need

- Isopropyl Alcohol (IPA), 90% or higher

- Lint-free swabs or a microfiber cloth

- A soft brush (optional, for loose dust)

- Compressed air (optional)

Step-by-Step Cleaning Process

- Power Down: First, completely turn off the device and disconnect the power supply.

- Expose the Connector: Carefully disassemble the device to get access to the LCD connector and the contact pads.

- Initial Dust Removal: Use a soft brush or a gentle puff of compressed air to remove any loose dust or debris.

- Apply IPA: Lightly dampen a lint-free swab with IPA. Do not soak it. You want it damp, not dripping.

- Wipe Gently: Carefully wipe the contacts on the FPC, the metal pins, or the pads for the Zebra Strip. Wipe in one direction to avoid pushing dirt back onto the contacts. For Zebra Strips, clean both the PCB and LCD glass pads.

- Let It Dry: Allow the alcohol to evaporate completely. This usually takes only a minute or two.

- Reassemble: Once everything is dry, carefully reassemble the connection and then the device.

What to Avoid

- Never use water or household cleaners. They can cause corrosion.

- Do not use cotton swabs. They can leave behind fibers that cause short circuits.

- Avoid scraping the contacts with metal tools, as this can cause permanent damage.

Conclusion

Choosing between FPC, Metal Pin, and Zebra Strip depends entirely on your product’s needs. Each has clear strengths for specific applications, from flexible electronics to rugged industrial gear.