Have you ever noticed faint ghostly images lingering on your industrial LCD screens? This is LCD burn-in, and it can severely impact your displays, but prevention is achievable.

LCD burn-in happens when static images remain displayed continuously, causing pixels to degrade unevenly, leading to permanent ghost-like marks on the screen, especially problematic in industrial settings.

Let me share a quick story. Last month, a customer from Turkey, Murat, experienced burn-in on our LCD modules installed on industrial equipment. He urgently asked how to resolve this issue. Here’s what we found.

What causes an LCD burn-in?

LCD burn-in isn’t a random occurrence. Knowing its cause helps protect your displays, saving time and costs.

LCD burn-in primarily occurs due to prolonged static image display, uneven pixel wear, excessive brightness settings, or using low-quality screens without proper quality control.

LCD burn-in causes:

Burn-in is primarily due to uneven aging of the liquid crystals and pixel components. When the screen displays static images for long periods, some pixels continuously remain active. Others remain inactive or less active, causing uneven aging. As the pixels age differently, persistent images become visible as faint shadows.

Here are some main contributing factors:

| Factor | Explanation | Prevention Suggestion |

|---|---|---|

| Static Images | Persistent static displays cause uneven pixel degradation. | Use dynamic or changing content regularly. |

| High Brightness | Increased brightness accelerates pixel degradation. | Maintain moderate brightness levels. |

| Poor-Quality Displays | Cheap components degrade unevenly. | Select high-quality LCD modules. |

| Continuous Operation | Non-stop usage leads to accelerated pixel aging. | Schedule regular screen rest periods. |

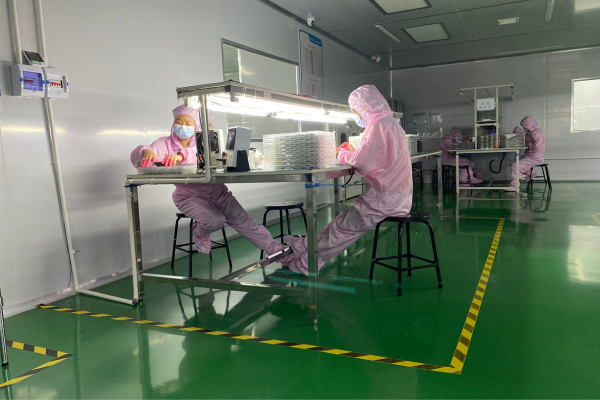

From my experience in supplying high-quality industrial LCD modules globally, especially for Europe and North America, poor quality modules accelerate burn-in. Investing in quality-certified LCD modules reduces burn-in significantly.

What’s the Effects of Image Burn-In on Industrial Displays?

Industrial displays, especially those operating 24/7, are highly susceptible to burn-in, and effects can disrupt operations severely.

Burn-in results in persistent ghost images, reduced readability, decreased overall image quality, and can even lead to operational inefficiencies or safety risks in critical environments.

Effects:

LCD burn-in doesn’t just affect visuals; it affects operations significantly, especially in industrial settings such as manufacturing plants or medical equipment.

Reduced Clarity and Visibility

The most obvious effect is reduced image clarity. Workers may struggle to read critical information clearly, increasing operational errors and compromising productivity.

Safety Concerns

In industries like manufacturing, aviation, or healthcare, unclear screens can cause errors, resulting in safety hazards. Imagine unclear navigation displays or unreadable medical device screens—it becomes a risk management issue.

Increased Operational Costs

Replacing or repairing burned-in screens increases operational costs significantly. Businesses sourcing from overseas suppliers like China face logistics delays, further exacerbating the impact.

How do you prevent screen burn-in?

Preventing burn-in is easier and more cost-effective than addressing it afterward.

Prevent screen burn-in by regularly changing displayed content, implementing pixel shifting technology, adjusting brightness settings, using screen savers, and investing in high-quality LCD modules.

Prevention Techniques:

Regularly Change Displayed Content

Frequently changing screen images prevents static pixel usage, thus reducing uneven degradation.

Pixel Shifting Technology

Pixel shifting subtly moves the displayed image periodically. It helps ensure all pixels age uniformly without noticeable changes to the viewer.

Use Screen Savers and Power Management

Industrial displays can benefit from screen savers or automatic dimming settings, reducing prolonged static exposure and saving energy.

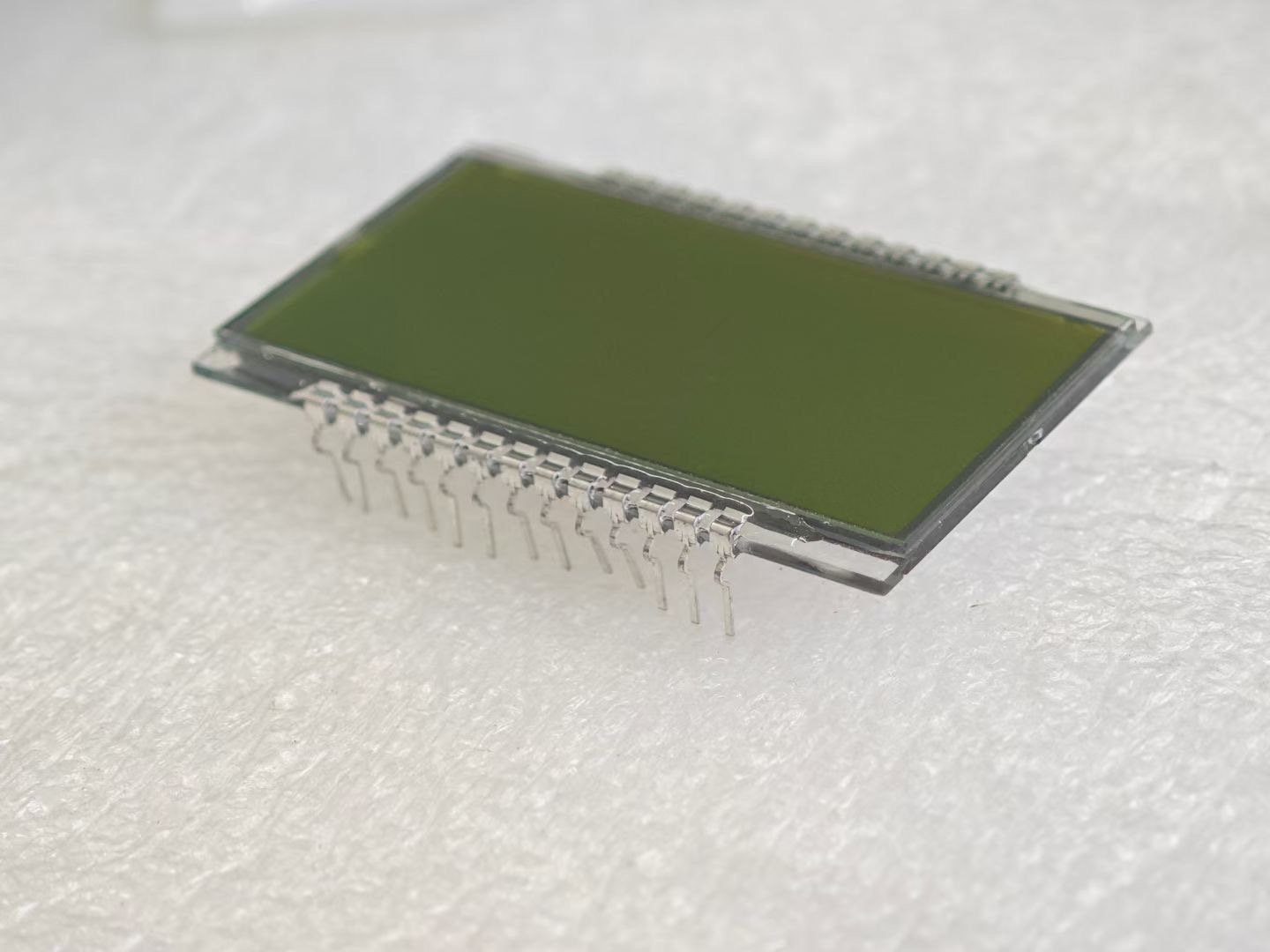

Selecting High-Quality LCD Modules

From our company’s experience at Santop, quality screens undergo rigorous testing. This significantly decreases susceptibility to burn-in, a vital consideration for industrial buyers.

How common is LCD burn-in?

LCD burn-in, although less common than OLED burn-in, remains a significant concern in industrial LCD applications.

LCD burn-in isn’t widespread among standard displays but becomes a critical issue in environments with constant static images, such as industrial, medical, and aviation industries.

LCD Burn-In Frequency:

While traditional LCD displays rarely experience significant burn-in under normal usage, industrial screens are an exception. Procurement officers like Murat, sourcing large volumes from China, India, or Brazil, frequently encounter burn-in due to 24-hour operational conditions. Our extensive experience with customers globally confirms this trend.

| Industry | Risk Level | Reasons |

|---|---|---|

| Consumer Displays | Low | Frequent content change |

| Industrial Displays | High | Static information, 24-hour use |

| Medical Displays | Very High | Persistent vital monitoring |

How to avoid LCD damage?

Burn-in is one type of LCD damage. Protecting your screens extends beyond burn-in prevention alone.

Avoid LCD damage by handling screens carefully during installation, controlling environmental conditions like humidity and temperature, using proper mounting methods, and following manufacturer guidelines.

Preventing LCD Damage:

Proper Installation and Handling

Incorrect handling during installation can permanently damage the liquid crystals or panel integrity. Ensure trained technicians install displays, following detailed manufacturer guidelines.

Controlling Environmental Conditions

Extreme humidity, temperature fluctuations, and dust affect LCD longevity. Ensure the environment stays controlled within recommended operational conditions.

| Condition | Recommended Range |

|---|---|

| Temperature | 0°C ~ 50°C |

| Humidity | 20% ~ 80% (non-condensing) |

| Dust Exposure | Use sealed industrial enclosures |

Regular Maintenance and Checks

Regular checks help identify early signs of damage, allowing quick intervention. My advice to Murat and similar customers is always the same: preventative maintenance saves costs long-term.

Conclusion

Understanding and preventing LCD burn-in protects your investment, ensures operational efficiency, and avoids costly downtime. Choosing quality screens and adopting preventative practices guarantees long-term performance and reliability.